Production lines used to run on checklists, clipboards, and coffee. Floor managers worked long hours, juggling schedules, reacting to hiccups, and trying to keep everything running smoothly. But those days are fading fast. With AI and machine learning moving into the world of production management, the entire process is getting smarter, faster, and a lot less reactive. Machines are now helping humans predict problems before they happen and making decisions that used to take teams of people. For businesses, it’s not just about saving time – it’s about getting better at everything.

Let’s look at how artificial intelligence and machine learning are quietly becoming the backbone of modern production, from forecasting what’s needed next to adjusting in real time when things go off track.

Smarter Forecasting: Reading the Future with Data

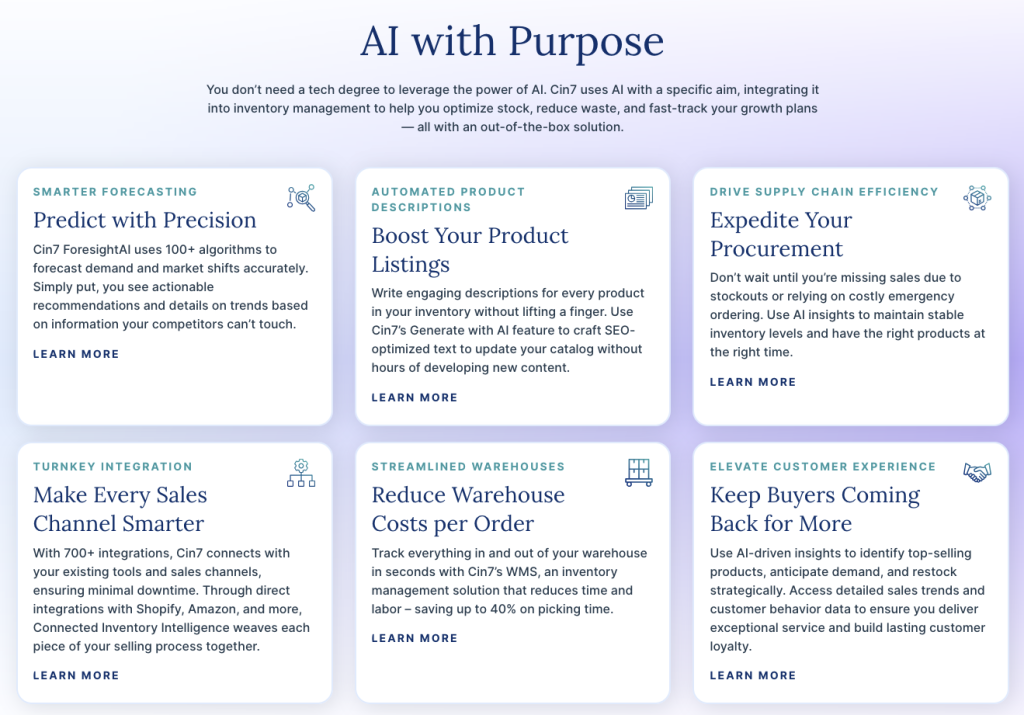

Imagine being able to know what your customers will want next week, next month, or even next year – not because you’re guessing, but because your system already figured it out. That’s the magic of predictive analytics, and it’s powered by machine learning.

Instead of relying on past reports or manual calculations, AI tools scan massive sets of data – orders, inventory levels, market changes, even weather patterns – and find patterns humans can’t easily spot. It doesn’t just look backward; it looks forward. If demand is expected to spike for a certain product, the system flags it ahead of time. That means businesses can order supplies early, adjust staffing, or shift their focus before things get messy. It also cuts down on waste. There’s no need to overstock items just in case. The guesswork disappears, replaced by a clearer picture of what’s coming.

When the entire workflow starts to align with actual needs, everything runs smoother. Fewer surprises. Fewer delays. Fewer costly missteps.

The Power Behind the Curtain

Here’s where it gets interesting. Predictive tools are only one part of the transformation. The real game-changer is something many factories and production teams are already starting to lean on without even realizing how much of a difference it makes.

Let’s talk about production management software. This isn’t just a fancy spreadsheet or an upgraded calendar. It’s a dynamic brain that connects the dots across departments and systems. It learns from what’s happened, watches what’s happening right now, and responds instantly to keep the line moving efficiently.

Say there’s a delay in one part of the process – maybe a machine goes down, or a shipment gets held up. Instead of waiting for a human to notice and rearrange things, the software adjusts schedules, reroutes jobs, and updates timelines in real time. It acts like a digital conductor keeping the orchestra in sync, without ever missing a beat. It’s not just automation – it’s intelligent automation. And the difference is huge.

Suddenly, operations that used to feel slow and clunky become flexible and fast. Communication gaps close. Wasted time shrinks. Everyone stays on the same page, because the system keeps them there.

Automated Scheduling: Rolling with the Punches

Scheduling might sound simple-until you’re managing hundreds of tasks, dozens of machines, and tight delivery windows. Traditional planning tools can’t always keep up when things shift. And in production, things always shift.

With AI-driven scheduling, the plan doesn’t freeze the moment it’s made. It lives and breathes. If an order changes, or a line starts moving faster than expected, the system adapts automatically. It’s like having a planner who never sleeps, constantly adjusting to get the most out of every hour and every machine.

This also makes life easier for workers. Instead of scrambling to understand new tasks or wondering what’s next, employees get clear updates, better direction, and fewer surprises. That means less stress and more confidence on the floor. And when the people running the machines feel supported by the tools guiding them, everything tends to run better.

Real-Time Monitoring: Eyes Everywhere, All the Time

One of the biggest shifts AI brings to production is how we see what’s happening-right now, not later. Real-time monitoring means exactly what it sounds like: the system watches every part of the operation as it happens and reacts fast when something goes off script.

Sensors on machines, barcode scans, or even camera feeds get processed instantly. If a bottleneck is forming, the system sees it before it becomes a problem. If equipment starts showing signs of wear, it can schedule maintenance before the breakdown happens. That keeps everything running, and cuts down on downtime in ways old systems never could.

There’s also a big bonus that comes with all this visibility: better data trails. Every move leaves a trace. That helps with tracking, with audits, and with long-term planning. AI impacts digital footprints by turning every tiny action into usable insight. Over time, this helps teams understand what’s really working-and what needs to change.

Getting Better Every Day: Machine Learning on the Floor

Unlike tools that stay the same over time, machine learning systems actually improve the more they’re used. They take in new data, compare it to old outcomes, and sharpen their predictions. In production, that means systems start recognizing which jobs usually take longer, which suppliers tend to delay shipments, or which machines always need extra prep time.

That insight doesn’t just help with scheduling-it helps with purchasing, staffing, maintenance, and quality control. Think of it as building muscle memory for the entire operation. The more the system learns, the better it can guide decisions and avoid mistakes.

And because these tools never stop learning, they help businesses grow without losing their edge. As demand grows or new products are added, the system scales. It keeps the same tight grip on performance, even as things get more complex.

People Still Matter: Working with, Not Against, AI

It’s easy to hear all this and worry that the machines are taking over. But here’s the truth: AI and machine learning don’t replace people-they support them. The human side of production is still essential. What’s changing is how much of the guesswork, grunt work, and stress gets handed off to smarter systems.

Managers still make key decisions. Workers still run the floor. But now they have sharper tools, better information, and fewer headaches. Instead of racing to put out fires, teams can spend more time building, improving, and thinking ahead.

That kind of shift doesn’t just improve profits. It can improve morale. People want to do good work-and AI helps them do it smarter, faster, and with fewer obstacles.

Final Thoughts

Production is getting smarter, and it’s not just about new machines-it’s about intelligent systems that learn, adapt, and help people do their best work. With AI and machine learning woven into everyday tools, businesses are running tighter ships, making better decisions, and preparing for whatever comes next. The future isn’t just on the way-it’s already in motion.

Alexandra Chen

Related posts

Popular Articles

Best Linux Distros for Developers and Programmers as of 2025

Linux might not be the preferred operating system of most regular users, but it’s definitely the go-to choice for the majority of developers and programmers. While other operating systems can also get the job done pretty well, Linux is a more specialized OS that was…

How to Install Pip on Ubuntu Linux

If you are a fan of using Python programming language, you can make your life easier by using Python Pip. It is a package management utility that allows you to install and manage Python software packages easily. Ubuntu doesn’t come with pre-installed Pip, but here…